Introduction to Counterbalance Assembly

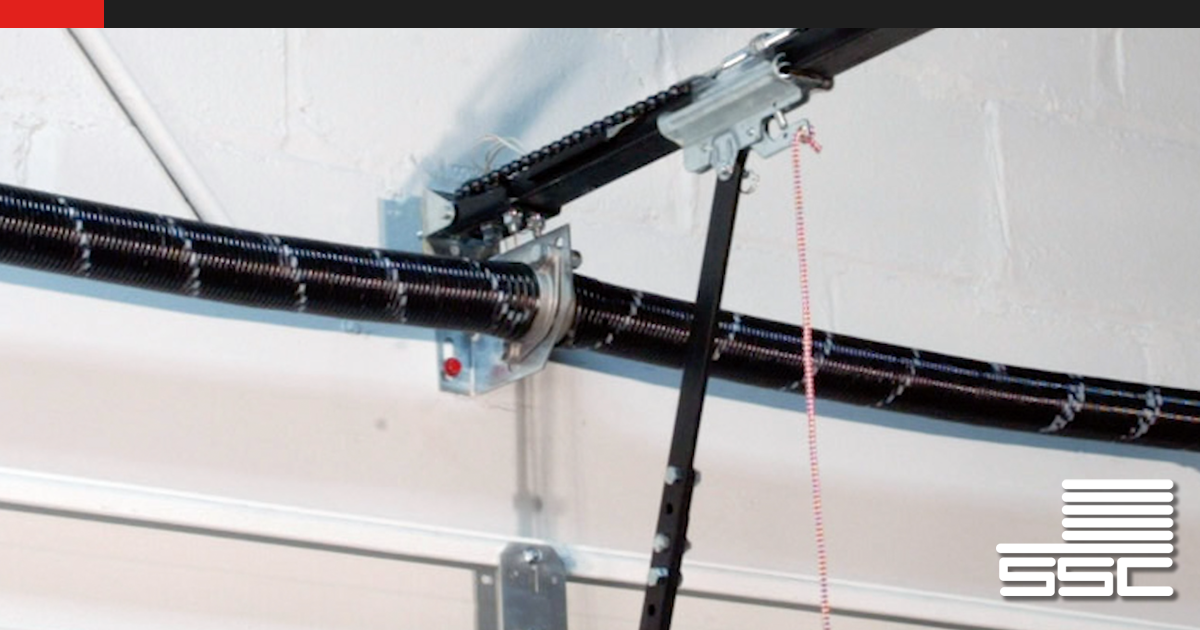

The counterbalance assembly does the heavy lifting of any garage door. Without it, the garage door is dead weight. The main components of the counterbalance assembly are the springs, drums, cables and cones, shaft, center and end bearing plates.

Let’s look at each of the components individually to understand their contribution to the counterbalance assembly.

Torsion Springs in the Counterbalance Assembly

The torsion spring provides the lifting capability of the counterbalance assembly through the door shaft and drums, to the cables attached at the door. Torsion springs are specifically designed and manufactured to create a lifting force.

A torsion spring is made by bending raw wire into a specific inside diameter (I.D.). Inside diameters can range from just over an inch to almost 8 inches. Wire size and wire diameter can range from 0.125 inches to up to 0.625 inches. Springs are coated and then stenciled with the corresponding wire size or diameter and the length of the torsion spring as well as color coded.

After the spring is produced, the winding cone and stationary cone can be installed. This can be done by SSC at our manufacturing location or in the field. On one end of the spring, the stationary cone is used to secure the torsion spring to a center bracket. The other end of the spring, known as the winding end, has the winding cone installed. An installer uses winding bars to wind the winding cone and then secure the torsion spring to the torsion shaft with the set screws. After a torsion spring is wound, it uses the counterbalance force created as an equalizer for the garage door. A wound torsion spring holds a lot of torque and can be very dangerous; however, it is still the safest type of spring for a homeowner as it is contained on the torsion tube or shaft and will not break away or fly throughout the garage when broken.

Each door is unique, but with more standardization than ever before, there are some common specifications that should be mentioned. Most residential torsion springs have an I.D. of 1-3/4” or 2”. Residential single wide doors typically have one torsion spring while double wide doors have 2 torsion springs. As stated before, each door and application is unique. You should never assume a past spring is correct or guess on what should be used. We recommend always engineering a spring for every application.

A well-balanced garage door should move easily through its operation by hand and be able to stop half way without going up or falling down. A garage door is balanced by a correctly installed and wound torsion spring.

SSC’s Solutions Education is a great, free resource to increase your garage door knowledge and learn tips and tricks from experts. Sign up now!

Pro Tip: To simplify spring engineering, download the SSC Spring Engineering Mobile application for Apple and Android or download SSC Spring Engineering Desktop for PC or Mac. This software allows you to easily enter the door dimensions and/or spring specs to calculate the size of replacement garage door springs.

Garage Door Cones in the Counterbalance Assembly

Connecting the spring and its lifting force to the rest of the assembly makes cones critical to the counterbalance assembly. Cones can come in many different shapes and sizes. Typically, there is always one stationary cone and one winding cone on each torsion spring. There are two main ways to assemble cones on springs – manually in the field or mechanically while SSC is manufacturing the springs.

Types of Plates for Counterbalance Assembly

There are 2 different types of plates – the center bearing plate and the end bearing plate. The purpose of both bearing plates is to allow the shaft to spin freely and still be securely fastened to the garage wall preventing the spring from coming off in case of breakage. Center brackets have a dual role, first being to contain the power of the torsion spring in an idle position and the other is to center the shaft inside the springs to prevent wear or damage.

Garage Door Shaft for Counterbalance Assembly

The shaft component of the counterbalance assembly is similar to a drive shaft in a car. It takes the power from the motor or springs and transfers it from the wheels or drums in order to raise and lower the garage door. The shaft runs through the bearing plates, springs, cones, and drums which all attach to the shaft. The shaft can be either solid steel or hollow steel tube and can also be keyed or unkeyed.

Drums & the Counterbalance Assembly

Drums are like the wheels on a car. Where the motor transfers energy from the drive shaft to the wheels, the torsion springs transfer power through the shaft to the drums. The drums are secured to the shaft on the inside of the end bearing plates. And then cables are attached from the drums to the bottom of the garage door. When the drums turn due to the unwinding of the springs, the cables wrap around lifting the door.

Repairing or building a counterbalance assembly is a common task for garage door technicians. The average life cycle for a garage door assembly is a minimum of 10,000 cycles. Since most families use their garage door as the main entrance into their home, the garage door may see the 10,000 cycles within 5-7 years on average. This means that the typical homeowner will come across a broken spring and need a replacement.

Are you a visual learner? Try SSC Solutions Education

SSC has spent more than 10 years developing our Solutions Education online video training platform to help professional garage door installers and dealers learn the in’s and out’s of the industry. Our INT01: Introduction to Counterbalance Assembly outlines the information above in an easy to follow instructional video and short quiz. Once the course is completed and the quiz is passed, it can be submitted to IDEA for CEU credits. Additional instructional videos for basic industry knowledge, customer service and garage door installation and repair are all available for free to SSC customers.

Service Spring, Your Supplier of Choice

Here at SSC we pride ourselves on being the manufacturer and supplier of choice for the overhead door industry. With more than 55 years of experience, we’ve built relationships with garage door dealers, installers and technicians from around the world. Our unique approach to customer service, American manufacturing and trusted delivery have made us a leading manufacturer and distributor of garage door replacement parts.

Related:

Share:

Safety Disclaimer: In order to see all procedures completely, there may be safety measures that are not taken by our actors. Be sure to follow any and all proper safety requirements and refer to your manufacturer’s installation manual for details. Your health and safety is the #1 concern. Failure to understand/follow the recommendations in the course could result in property damage, personal injury or death. While all efforts are made to provide accurate information and guidance, it is impossible to predict all door circumstances. Accordingly, the user agrees that the user of this video; products and information contained herein are at your own risk. In no event shall Service Spring be liable for any property damage, personal injury/death, or any other loss or damage that may result from your use of the information and products provided on this video. All information contained within this site is provided “as-is” without warranty expressed or implied. User assumes all responsibility/risk for use of information and products purchased. If you have any doubts about your ability to perform the work safely, we recommend you contact another door professional to complete your repair.